NdFeB Neodymium Iron Boron Magnets are generally coated with an anti-oxidant layer. The most commonly used coatings are those in nickel, zinc, epoxies, phosphates, with resins; without which, the magnets would oxidize in a short time, affecting their magnetic performance.

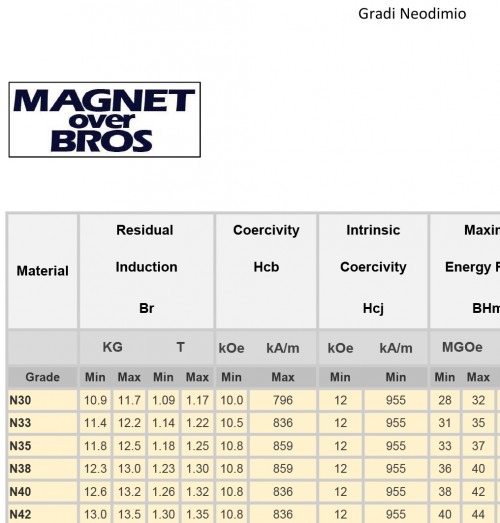

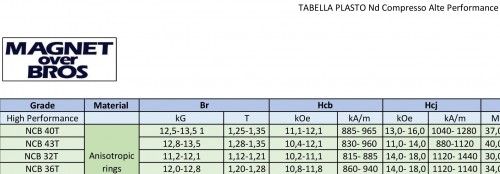

Today these magnets reach high quality grades such as: N54 - Maximum residual induction (Br) values of 15.2 KGs - Working temperatures above 230 °C - A maximum energy produced of 55 MGoe.

The most common formats are: DISCS - CYLINDERS - RINGS - BLOCKS - CUBES - SPHERE - SEGMENTS. But special shapes can also be created according to the customer's application needs.

The types of magnetization can be various: AXIAL - RADIAL - DIAMETERAL - MULTIPOLES