Neodymium magnets are those with the best magnetic performance, the most powerful among permanent magnets.

They are made of an alloy of boron, iron and neodymium. It is a strongly magnetic alloy; It has a silvery-white color, is fragile and is easily damaged.

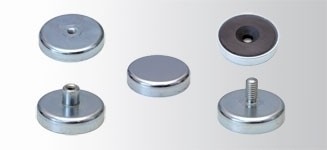

The two main processing techniques for these magnets are: sintering and compression

To find out more...Go to the page dedicated to Neodymium